kwired

Electron manager

- Location

- NE Nebraska

If you can produce a code section that requires this we will go with it. That bare aluminum conductor inside is nothing more then a bonding strip to short out each turn of the spiral sheath to reduce its impedance. It requires no special attention and is acceptable to trim it short after stripping cable sheath. But you can find countless ideas out there of how this thing is to be handled.I believe the tracer has to be visible to prove it is there and has not heen cut off... (which i have also seen guys do...)

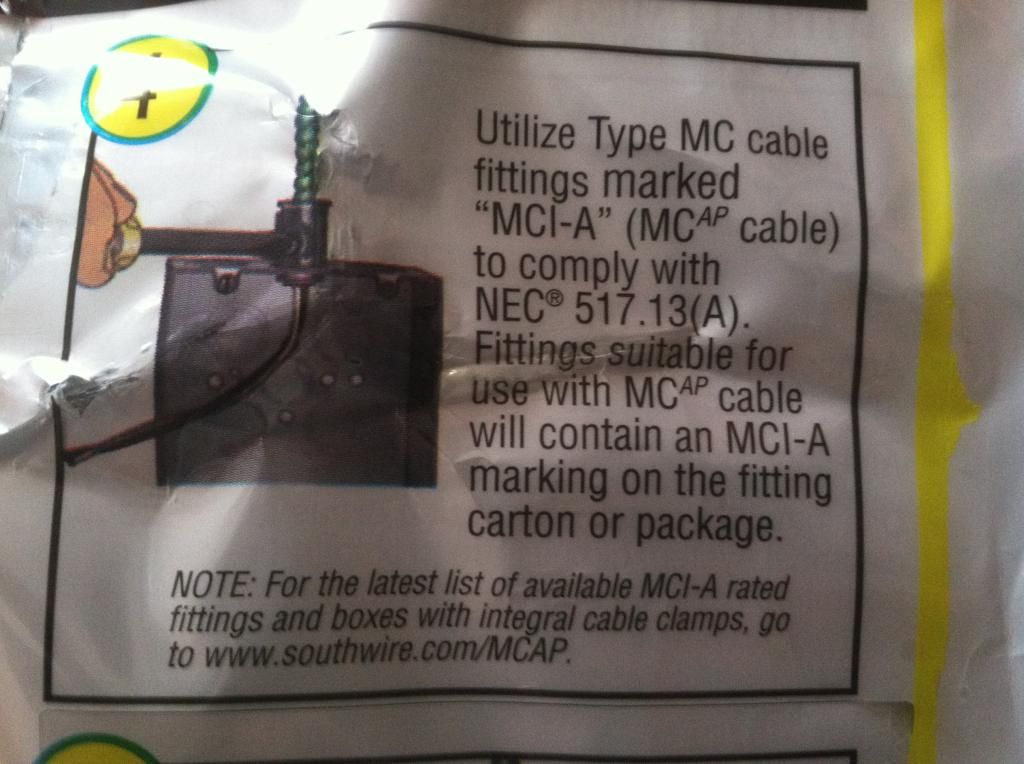

Most fittings out there meet those requirements, I know the single cable version of the one in first picture does meet necessary requirements for use in health care, as I have researched them before, not certain about the duplex versions though, but am leaning toward them also being compliant.From Southwire

We can't really see all of the first 12" to tell if it is properly supported, in picture 1.MC does not need an anti-short bushing.

Picture 1 not supported within 12" from box termination.

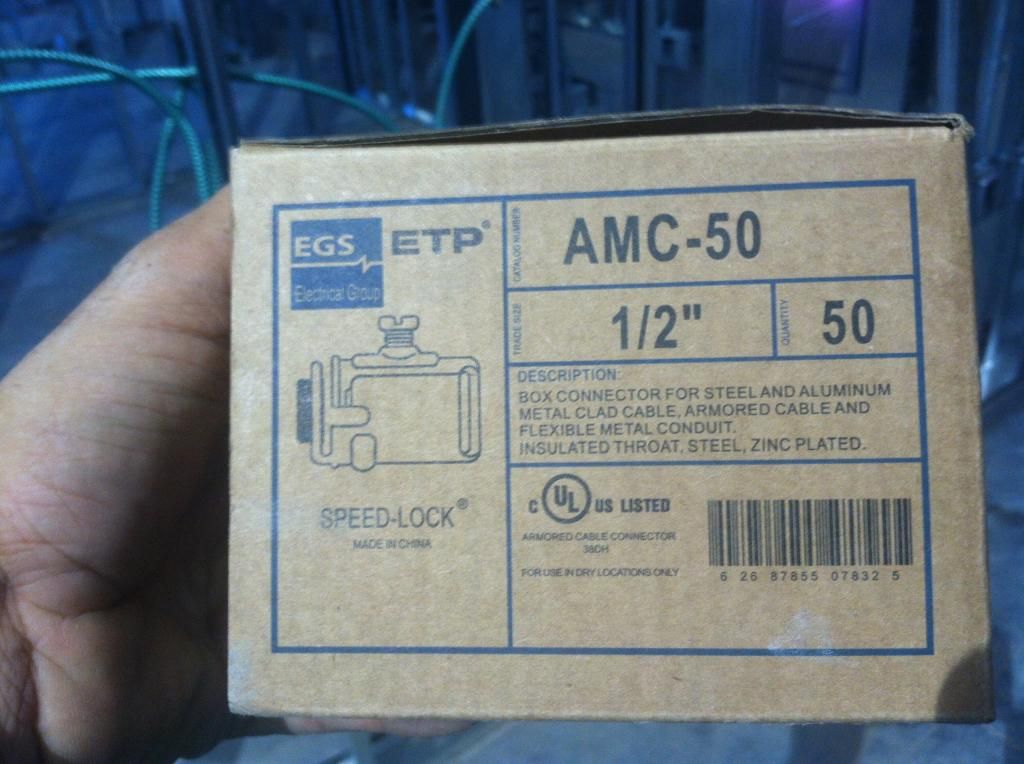

Not certain myself either, but am guessing the fitting is listed for use with aluminum sheath, I have seen advertising for these fittings but haven't used them.I'm going with pic # 2 being the violation, set screw connector and aluminum sheath do not go together. Although, it is hard to tell from the pic if these connectors are actual set screws that contact the sheath or if there is a wedge that the set screw traps against the sheath. The latter would negate my guess

so far all I see that I don't like is the set screws on the fittings in picture 2 appear to extend into space where the drywall will be placed.

Any other violations if they exist are going to be technical listing applications of a specific fitting, the box or the mud ring.