Cable assemblies he posted links to, are aluminum conductors, one bare conductor with one strand being a steel support wire - aluminum would stretch too easily if not for that steel strand. That bare is also normally used for the grounded conductor. Then there are insulated conductors wrapped around the bare messenger conductor. They usually have XLPE insulation - much more durable and able to withstand what they will be exposed to than THHN/THWN types of insulation. It is intended for aerial use only and not intended to be run in raceways or to be used below grade at all.

Running in free air gives it different ampacity characteristics than inside cable sheath or raceway. POCO's still use different ampacity selection methods than we use for NEC wiring though. But at same time we have to consider how hot we want to run something inside a building where their stuff is mostly outside buildings or in vaults if inside. If we overheat something there is risk of starting a fire, if they overheat something it is usually more isolated and not as much of a fire risk.

More conductor (of any size or type) between the source and any point of interest means more resistance across that distance which lowers available fault current, compared to what is available at the source. I keep telling you how incident energy is dependent on details. Simply adding 10 feet of supply conductor to an installation adds enough resistance to make a difference in lowering the available fault current to some degree. This is part of why fault current at dwellings is generally considered to be somewhat low - they often have some length of conductor between the dwelling service and the source transformer that is going to be current limiting to some degree, and just 10-20 feet of conductor makes a huge difference in a majority of installs.

After going through all these tangents-- the title is not appropriate to be called science anymore . . . let alone considered to be

“The Science of Arc Flash.”

From grounding, to blown circuit breakers to appropriate space suit, this whole topic is starting to be a joke.

Science and engineering are both in the same boat. . . they both work endlessly on something guided by their discipline.

Engineering assembles new things and a lot of these things that are put together are elements of old

things. From this effort, new interesting things and brand new things emerge.

Science is the systematic study of the nature of everything around us . The properties of materials and the physical universe that provide the necessary elements to cause things to happen. Science is rational while fundamentalism (which is where this whole thing is leading us to) is irrational. Science explains how things are-- based on accumulated facts.

Engineering accepts what had been generally accepted-- either by practice or results that seem to have the most benefit. So, engineers make the stuff while science takes that stuff apart and even reverse engineer.

The big difference between the two is: The engineer accepts what he consider is true. Scientists don't believe in anything. (you can't convince a scientist to believe what you think.)

Since scientists' work is continuum-- whatever they think that might be true at a time-- is good until new evidence shows up. Then they start from where they started to a point that they will ignore what had been accepted in the past.

Arc happens when there is presence of gas, the right type of gas for an arc to happen. This is aided by the interaction between the properties of materials along with electrical energy.

OP had evolved from serious scientific investigations which ignited curiosity including me, until it

became a litany of YouTube tidbits that offer no new useful information.

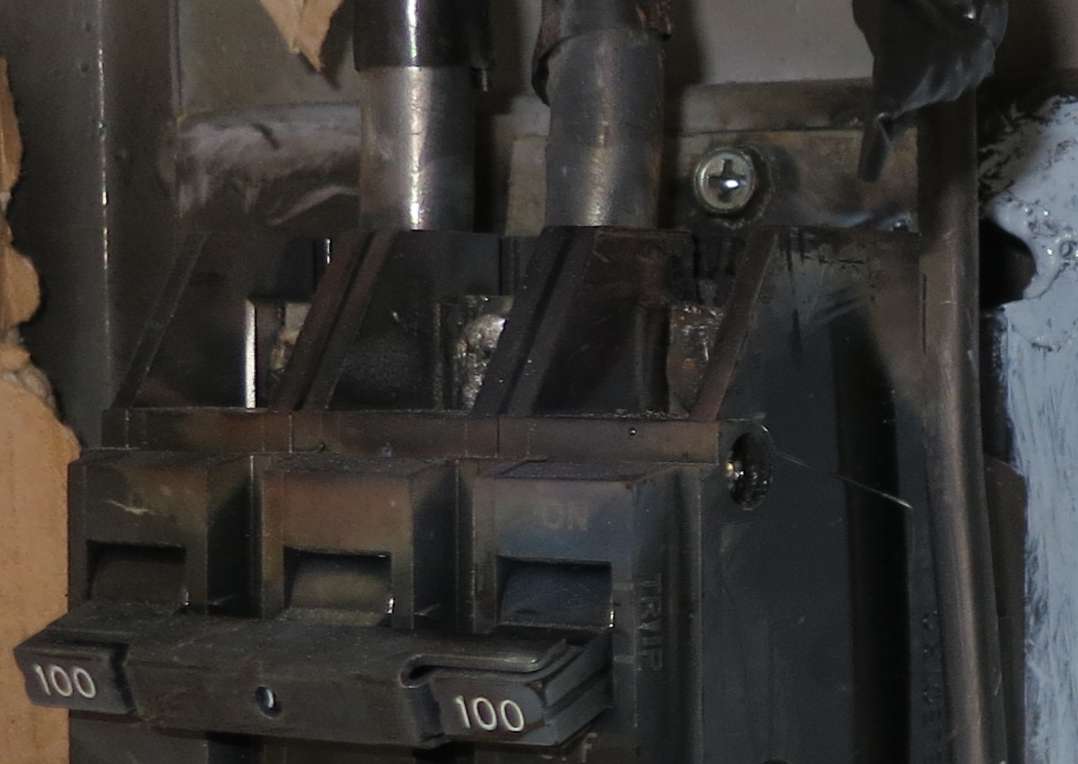

Instead of getting obsessed in posting super high definition pics of blown circuit breakers and burned wires and terminals--it would be more beneficial if investigations were focused on the cause of arc

flash.

How it started, how it can be prevented and what the contributing factor that led to it, would be worth the time spent.

The absence of this “scientific” information diminishes the dissemination of quality educational tools for learners.

The endless litany accompanied by high definition presentation (photos) might as well be called “thumb nails” of electrical

boo boos.

Blown panels and breakers don't possess the quality of incidents that deserve to be called science.