You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Paintbooth Enclosure Wiring

- Thread starter faresos

- Start date

- Location

- Mission Viejo, CA

- Occupation

- Professional Electrical Engineer

Surface mounted is a common option and usually acceptable; however, there are alternatives. See Section 516.6(C).

Thank you! The actual issue I'm facing, there is one paintbooth fixture recessed in wall that is close to paintbooth door (within 3-ft). My understanding anything within 3 ft (all direction) of any paintbooth opening needs to be Class I, Div 2. So, I'm not sure if this installation meet that NEC requirement. Any thoughts? ThanksSurface mounted is a common option and usually acceptable; however, there are alternatives. See Section 516.6(C).

- Location

- Mission Viejo, CA

- Occupation

- Professional Electrical Engineer

This moves the goalpost a bit. It depends on clearly defining the area classification boundaries. That is, is the luminaire actually in the hazardous location or not? If yes, then 516.6(C) applies.

I’m currently assuming that the luminaire is on the exterior of the paint booth. If it is in the interior, you might want to check your area classification.

I’m currently assuming that the luminaire is on the exterior of the paint booth. If it is in the interior, you might want to check your area classification.

Yes the luminaire is on the exterior of the paintbooth and serviced from the outside. To me, section 516.6(C)(1) applies. As I said, the confusing part for me, does the 3ft rule around any opening (in our case it's a man door) applies also to the wall cavity where the fixture and associated wiring is recessed in that wall? The only exception I see is in section NEC 516.5 (D)(4)(2):

"(2) Where automated spray application equipment is used, the area outside the access doors shall be unclassified provided the door interlock prevents the spray application operations when the door is open"

Does automated spry means robotic system and not actual person does it?

"(2) Where automated spray application equipment is used, the area outside the access doors shall be unclassified provided the door interlock prevents the spray application operations when the door is open"

Does automated spry means robotic system and not actual person does it?

- Location

- Mission Viejo, CA

- Occupation

- Professional Electrical Engineer

I don’t know which NEC Edition you are referring to. Lately, I have been citing the 2023 Edition.

Figure 516.5(D)(4) in the 2023 NEC indicates the interior of the recess is Division 1. That's what I was hinting at earlier. I also suggested reviewing Section 516.6(C). That was an error.

It should have been 516.4(C), especially Figures 516.4(C)(1)&(3).

Figure 516.5(D)(4) in the 2023 NEC indicates the interior of the recess is Division 1. That's what I was hinting at earlier. I also suggested reviewing Section 516.6(C). That was an error.

It should have been 516.4(C), especially Figures 516.4(C)(1)&(3).

petersonra

Senior Member

- Location

- Northern illinois

- Occupation

- engineer

I think the top and bottom openings are sealed devices located on the back side of the wall, while the side ones are maybe doors of some sort? Although why the inside of the spray booth adjacent to the door would only be div 2 and the rest of the interior of the spray booth is div 1. So that is probably not it.

MTW

Senior Member

- Location

- SE Michigan

It could be helpful to your cause if you specified the cut sheet to the fixture your using, and whether the booth wall is a bare or insulated panel. Depending, fixtures can be mounted exterior to the panels or inside the panels, their listing classification is a determining factor on how they can be wired.Thank you! The actual issue I'm facing, there is one paintbooth fixture recessed in wall that is close to paintbooth door (within 3-ft). My understanding anything within 3 ft (all direction) of any paintbooth opening needs to be Class I, Div 2. So, I'm not sure if this installation meet that NEC requirement. Any thoughts? Thanks

Paint / Powder / Blast Booth

Inside the spray booth is CI, D1 per the solid hatching. If you look at the elevation you can see the top of the hatch (CI, D2) stops at the top and doesn't extend down to inside the booth or even interior walls or ceilings.I think the top and bottom openings are sealed devices located on the back side of the wall, while the side ones are maybe doors of some sort? Although why the inside of the spray booth adjacent to the door would only be div 2 and the rest of the interior of the spray booth is div 1. So that is probably not it.

these fixtures are installed outside of the spray area.It could be helpful to your cause if you specified the cut sheet to the fixture your using, and whether the booth wall is a bare or insulated panel. Depending, fixtures can be mounted exterior to the panels or inside the panels, their listing classification is a determining factor on how they can be wired.

Paint / Powder / Blast Booth

MTW

Senior Member

- Location

- SE Michigan

For listed booth fixtures installed outside of the hazardous areas as shown in your NEC drawings above, away from booth openings, non hazardous wiring methods apply.

For fixtures installed within the hazardous zone (near doorways or openings) Class I, Div 2 methods apply. Anything on the interior of the booth barrier wall needs to be Class I, Div 1.

A rated glass panel that is sealed to the booth wall opening is considered part of the booth wall, and separates the hazardous area from the nonhazardous.

From the cut sheet you provided I don't understand your use of the words "wall cavity where the fixture and associated wiring is recessed in that wall?

You appear to have a single wall construction which is the barrier, what do you mean by the wall cavity? You can only be on one side of the barrier wall or the other, unless you have insulated panels, and that is not what your cut sheet shows.

For fixtures installed within the hazardous zone (near doorways or openings) Class I, Div 2 methods apply. Anything on the interior of the booth barrier wall needs to be Class I, Div 1.

A rated glass panel that is sealed to the booth wall opening is considered part of the booth wall, and separates the hazardous area from the nonhazardous.

From the cut sheet you provided I don't understand your use of the words "wall cavity where the fixture and associated wiring is recessed in that wall?

You appear to have a single wall construction which is the barrier, what do you mean by the wall cavity? You can only be on one side of the barrier wall or the other, unless you have insulated panels, and that is not what your cut sheet shows.

I would concur, it's a single wall construction (barrier) that separate the hazardous area from the nonhazardous. The part that now I'm not sure about is Figure 516.5(D)(4), top & side elevation, they way it reads to me now that the interior wall within 3ft of the opening of the enclosure is not included (hatched) which means it's not classified unless I'm not reading it correctly.

MTW

Senior Member

- Location

- SE Michigan

MTW

Senior Member

- Location

- SE Michigan

Back the within the walls??? There is an inside or an outside, what is within? The only way to have a within the wall is with an insulated panel. In wiring booths for more than 30 years I only ever encountered one booth style that had indulated panels with the fixture in the walls and they had molded glass covers to enclose the fixtures and haven't made that type in many years. I think your reading into the illistration more than need be. It's a single barrier wall, can't have a within with only one layer construction, even though the illustration may look like it.

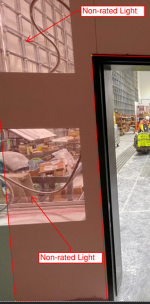

MTW, thanks for your input. Here is a photo of what I'm referring to. As you, these openings, which is with 3ft of the door, are for light fixtures (not rated for hazardous locations) and has a glass panel that separate it from paintbooth interior. The wiring goes inside the walls or whatever you want to call them.Back the within the walls??? There is an inside or an outside, what is within? The only way to have a within the wall is with an insulated panel. In wiring booths for more than 30 years I only ever encountered one booth style that had indulated panels with the fixture in the walls and they had molded glass covers to enclose the fixtures and haven't made that type in many years. I think your reading into the illistration more than need be. It's a single barrier wall, can't have a within with only one layer construction, even though the illustration may look like it.

Attachments

MTW

Senior Member

- Location

- SE Michigan

If the light is within 3' of the man door, it must be rated for the application, spray booth CL1, Div2 if your fixture is not rated you cannot use it, nor can you have normal wiring methods within that zone.

Here is you an example of an approved fixture, listed for the purpose.

https://www.ldpi-inc.com/applicatio...cess-industrial-led-paint-booth-light-fixture

Read the spec sheet and installation manual shown on the page link. If the fixture you have has no such listing it cannot be used next to the man door or any other opening. Even if the booth wall has a glass panel installed in it. This why I asked early on if you could provide a fixture cut sheet.

I cant tell anything about the fixture from the picture you posted, if it's not rated and listed you don't want to use it, for your own liability.

Here is you an example of an approved fixture, listed for the purpose.

https://www.ldpi-inc.com/applicatio...cess-industrial-led-paint-booth-light-fixture

Read the spec sheet and installation manual shown on the page link. If the fixture you have has no such listing it cannot be used next to the man door or any other opening. Even if the booth wall has a glass panel installed in it. This why I asked early on if you could provide a fixture cut sheet.

I cant tell anything about the fixture from the picture you posted, if it's not rated and listed you don't want to use it, for your own liability.