Mr. Serious

Senior Member

- Location

- Oklahoma, USA

- Occupation

- Electrical Contractor

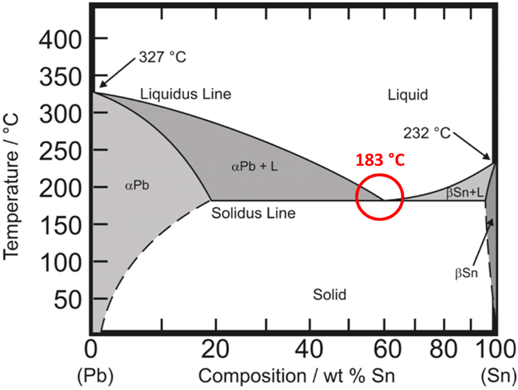

63/37 is known as "eutectic" point if I recall correctly. Something about the metallurgy allows for a precise melting point at that exact blend of tin and lead. Any other blend will melt and solidify slower, because the temperature will change by several degrees during the melting/freezing process. So, it's easier to use the solder with the 63/37 blend.

You can still use lead-based solder for electronics, but you can't sell the resulting product in the EU or in California. I don't think anybody yet knows if there is a non-lead solder that will perform as well over the long term.

You can still use lead-based solder for electronics, but you can't sell the resulting product in the EU or in California. I don't think anybody yet knows if there is a non-lead solder that will perform as well over the long term.