I'd wager a bet its open delta for two reasons:

1) A closed delta secondary - wye grounded primary turns the bank into a "grounding transformer", meaning faults on the primary line will cause nuisance fuse blowing on the bank. The solution to that is a delta or ungrounded wye primary (which is great) but susceptible to ferroresonance during single pole switching at voltages over 12kv.

Which leads me to ask, how many volts is your primary system? 34.5kv by chance?

2) Being that in your area everything is connected phase-phase on the LV, you would need a 138 volt transformer to get 240 volts on a wye secondary. This is the ideal solution- but such are rare in the US and really unheard of in many places. Thus the only way to get 240 volts from standard US pole pigs is to connected the secondary in delta.

Anyway- This is a good read:

https://myelectrical.com/notes/entryid/254/what-is-an-open-delta-transformer

at voltages above 12kv can produce ferroresonance

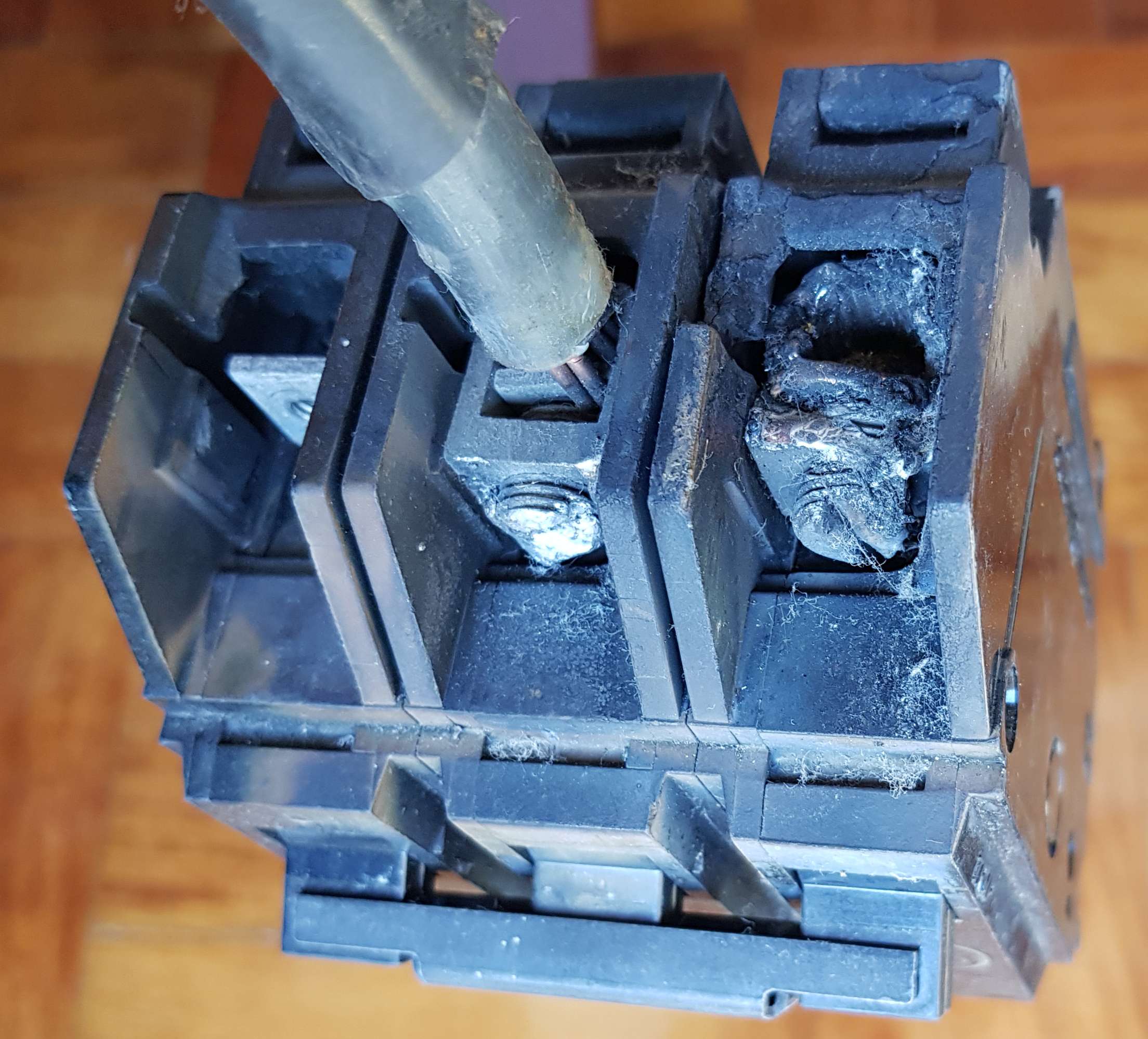

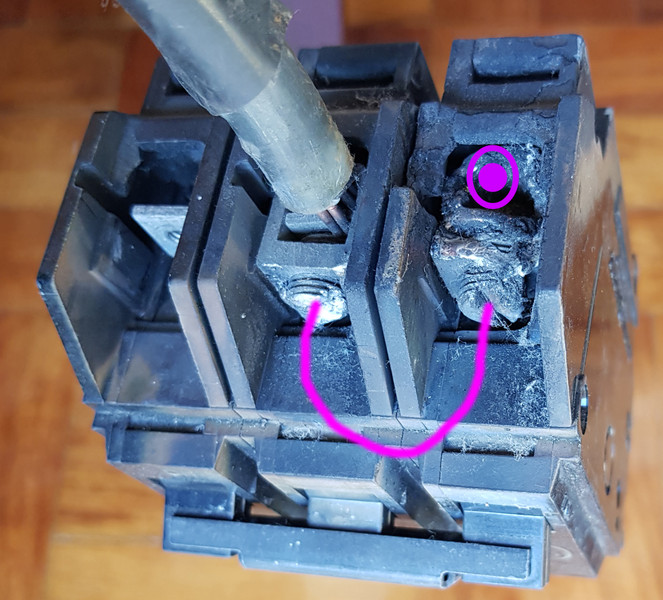

I'll ask the power company what is the exact primary voltage. I forgot. My concern about all this is because the panel in the office building can't be considered Arc Flash Category 0. It is Category 1. So I'm contemplating what kind of PPE to buy to let the electrician wear next time he would open it because I'm nervous already due to the experience in 2015. Also I read:

https://www.ecmweb.com/content/keys-understanding-nfpa-standard-70e

"The key numbers to remember are 1.2 and 40. Incident energy levels greater than 1.2 calories per centimeter-squared can produce second-degree burns. Flame-resistant garments are necessary for protecting yourself against possible burns caused by energy levels above 1.2. Arc-flash energy levels above 40 can be fatal because they're accompanied by a massive pressure blast and sound pressure waves, which produce projectiles. Clothing is available for arc-flash exposures all the way up to 100 calories per centimeter-squared, but it's useless against the force of the pressure blast."

I'm reading this paper too:

https://ep-ca.mersen.com/fileadmin/...fecting-Sustainability-of-Arcs-Below-250V.pdf

"Investigation Of Factors Affecting The Sustainability Of Arcs Below 250V"

However if mwired or other arc flash experts can convinced me there is no way carbon deposit itself can initiate arc flash between phase to phase terminals of breakers. Then I can forgot all of the above, lol.

I'm reading this paper too:

https://ep-ca.mersen.com/fileadmin/...fecting-Sustainability-of-Arcs-Below-250V.pdf

"Investigation Of Factors Affecting The Sustainability Of Arcs Below 250V"

However if mwired or other arc flash experts can convinced me there is no way carbon deposit itself can initiate arc flash between phase to phase terminals of breakers. Then I can forgot all of the above, lol.