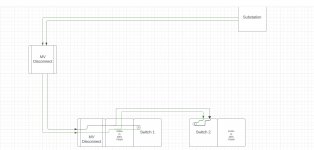

We have a data center that runs alot of equipment at 240v at the plug.

We get this by stepping 4160v (coming from substation outside) down to 432v. Our 3 phase PDUs are taking hot to neutral so we wind up with a voltage higher than 240v but with added load it drops to desired range.

This system is setup with GE switchgear coming off the transformer secondary and the transformer grounding bar is ran to the switchgear grounding bus. Inside the switchgear the neutral and ground are bonded.

Here’s the problem, the electricians swear that you don’t need to ground the switchgear or the transformer to a building column or a close by rod. This seems to directly conflict with NEC 250.30 because the 4160v to 480v transformer (delta to WYE) is absolutely a separately derived system.

What we have noticed is that we have ground current (3-30amps) at super low voltages running thru every panel in the circuit. Voltage is less than .4v.

The ONLY ground that exists runs from the 4160 step down all the way back to the substation which is 700-1000FT away and that’s generous. At those amps and volts the ground basically doesn’t exist so the current is trying to find other paths.

I’ve tried to tell the electricians to ground the switchgear bus to the building column 10FT away but they continue to tell me that the ground to the sub yard is sufficient. When clearly it isn’t.

Am I wrong? Are they wrong? This seems clear cut.

We get this by stepping 4160v (coming from substation outside) down to 432v. Our 3 phase PDUs are taking hot to neutral so we wind up with a voltage higher than 240v but with added load it drops to desired range.

This system is setup with GE switchgear coming off the transformer secondary and the transformer grounding bar is ran to the switchgear grounding bus. Inside the switchgear the neutral and ground are bonded.

Here’s the problem, the electricians swear that you don’t need to ground the switchgear or the transformer to a building column or a close by rod. This seems to directly conflict with NEC 250.30 because the 4160v to 480v transformer (delta to WYE) is absolutely a separately derived system.

What we have noticed is that we have ground current (3-30amps) at super low voltages running thru every panel in the circuit. Voltage is less than .4v.

The ONLY ground that exists runs from the 4160 step down all the way back to the substation which is 700-1000FT away and that’s generous. At those amps and volts the ground basically doesn’t exist so the current is trying to find other paths.

I’ve tried to tell the electricians to ground the switchgear bus to the building column 10FT away but they continue to tell me that the ground to the sub yard is sufficient. When clearly it isn’t.

Am I wrong? Are they wrong? This seems clear cut.