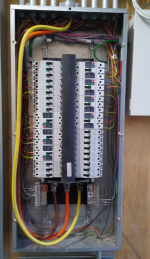

Why are they using a 3 phase panel and putting OCPD on the grounded conductor? To facilitate a future changeover to 240V 4-wire hi leg delta? I guess that would just require removing a lot of white tape.

Cheers, Wayne

For this application it was designed that way. The GEC is at transformer.

Pretty sure 240.22. (1) allows this to have a three pole main breaker.

I was late to this party as they did not understand the wireing methods involved. Since I had experience with these installs I helped them square it away. I had recommended B phase be grounded and use black,white, blue and use all striped wire since there three other systems in the building.

They had already pulled branch circuits,BK,R,BL which had to be reworked. Then I did my best to explain the grounded conductor to them as well as do and don't.

the first hurdle was the word netural. Next was hooking a white wire to breaker. Then what to do at the equipment. This system was for special 240 volt only equipment. No vfd all across the line. Depending on the type of disconnect required a different hook up. Non fused break both ungrounded and grounded. All were either two pole or three pole.

fused required a dummy in the grounded conductor.

the panel and breakers all rated for the delta. I also told them to ring all wires you do not want a short in the grounded conductor to EGC.

the GEC had to be resized correctly as well.

And of course lable,labe lable.

As far as tape went I said you need to pull the correct color of conductors for that system all the way thru and don't use tape.

Any way the choice was made to go C grounded and use black, red, white on the feeders and remark the branch. Once they were brought up to speed I was removed from project. I also had to have them re work all GEC s etc to the correct size. Told them #6 is not per NEC. For the entire grounding electrode system and multi SDS's. #6 for rods only.

The funny thing ( sad really)was on a 480 volt feeder there was no netural to the 277/480 volt panle.

Then this a three section. The pics speak for them selves. I said tare it all out start over.

Sorry a little rant.