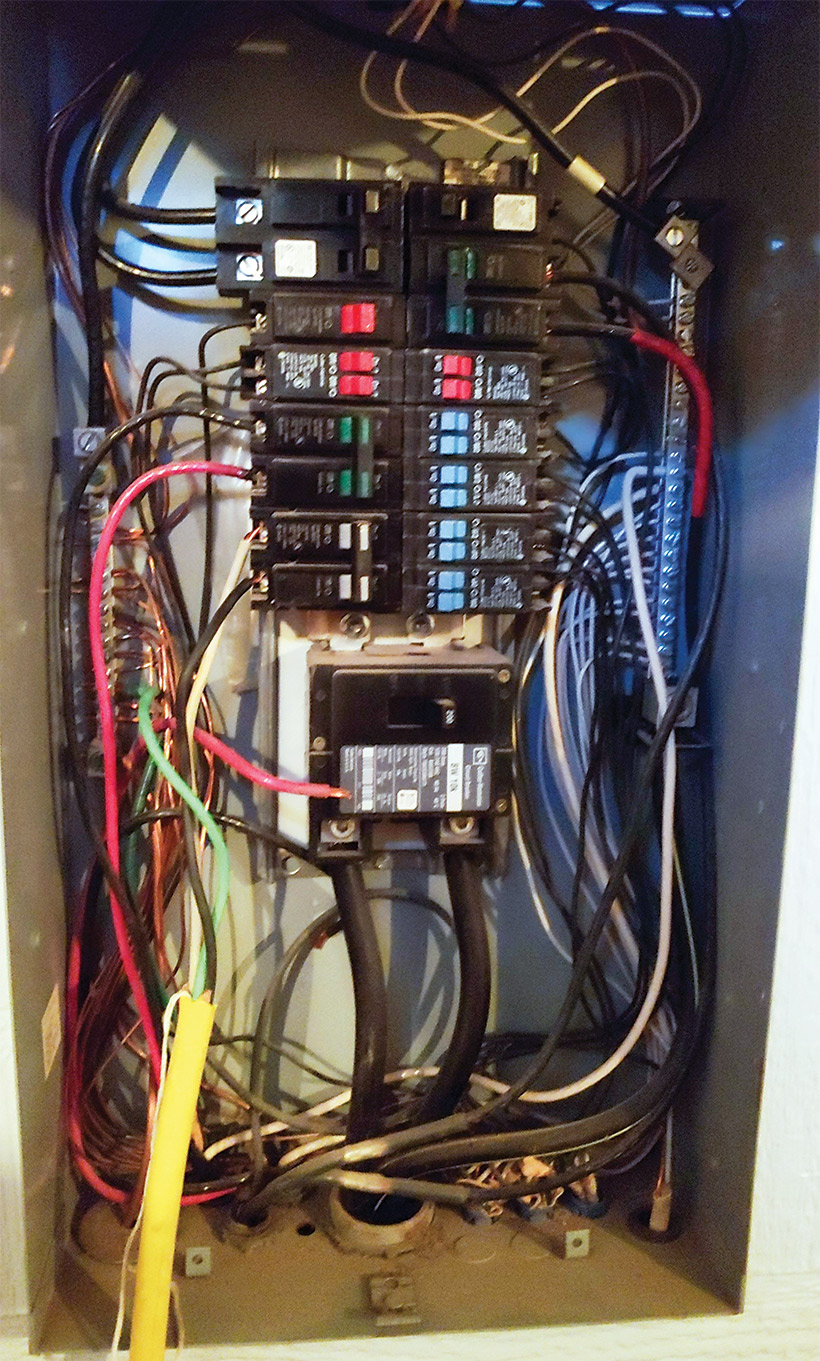

Got a call yesterday from the owner of a townhouse, having issues with a breaker tripping. I assumed it was an AFCI and I can't stand those types of calls. But I stopped by early this afternoon to check it out.

I remove the panel cover and check the connections on breaker no. 13, which is off and is marked "LR and MBR outlets". Nothing unusual there. But just out of habit, I check every terminal in the panel.

I just about filled my drawers when I worked my way up the breakers to the 40a 2p for the range.

There's a 2011 inspection sticker on the panel. I've got a dollar that says this breaker's terminals were never tightened down 9 years ago. Amazing that the range even worked, let alone didn't melt the breaker at some point.

I usually find one or two terminations in every panel I open that could benefit from a bit more torque. But this one just floored me.

I remove the panel cover and check the connections on breaker no. 13, which is off and is marked "LR and MBR outlets". Nothing unusual there. But just out of habit, I check every terminal in the panel.

I just about filled my drawers when I worked my way up the breakers to the 40a 2p for the range.

There's a 2011 inspection sticker on the panel. I've got a dollar that says this breaker's terminals were never tightened down 9 years ago. Amazing that the range even worked, let alone didn't melt the breaker at some point.

I usually find one or two terminations in every panel I open that could benefit from a bit more torque. But this one just floored me.