hhsting

Senior Member

- Location

- Glen bunie, md, us

- Occupation

- Junior plan reviewer

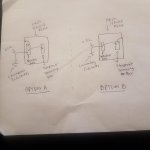

As main service disco I have 200A panelboard with 200 MCB. You are suppose to bond the non current carrying metallic service disconnect enclosure to which one of the following and where is it stated in code:

1. Neutral bar

2. Equipment grounding conductor bar

no its not a test question.

1. Neutral bar

2. Equipment grounding conductor bar

no its not a test question.