electro7

Senior Member

- Location

- Northern CA, US

- Occupation

- Electrician, Solar and Electrical Contractor

Hi,

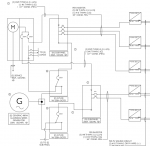

I have attached an installation where the plan checker is pushing back on our design using the feeder tap rule. Attached is the original design, then the revised design, along with with his plan check comment, which is the same for both (it doesnt make sense to me).

Questions:

1. Is the original (first) design with the new 200A sub-panels used code compliant according to 705.12(B)(2)(1)(b)? I see it similar to a feeder tap although had question on whether the connection point between the solar breakers and the bussing would overheat.

2. The revised (second) design is okay from everything I have been taught but please let me know if you feel the same or differently- that it does comply with 705.12(B)(2)(1)(b) or not.

Thanks ahead of time for your help.

I have attached an installation where the plan checker is pushing back on our design using the feeder tap rule. Attached is the original design, then the revised design, along with with his plan check comment, which is the same for both (it doesnt make sense to me).

Questions:

1. Is the original (first) design with the new 200A sub-panels used code compliant according to 705.12(B)(2)(1)(b)? I see it similar to a feeder tap although had question on whether the connection point between the solar breakers and the bussing would overheat.

2. The revised (second) design is okay from everything I have been taught but please let me know if you feel the same or differently- that it does comply with 705.12(B)(2)(1)(b) or not.

Thanks ahead of time for your help.