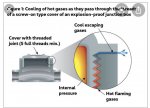

The main text of section 500.8(E) outlines proper "threading" in hazardous locations. It must not hinder continuity since even a slight current arc, whether fault induced or circulating from harmonics could cause an ignition. This is a problem even in Division 2 since harmonic currents could be continuous. Also "plugging" a thread with compound could affect the pressure relief effect at a thread during an internal ignition.

It should also be recognized that corrosion protection coatings, while desirable, does have a specific exception at threaded joints in section 300.(A). Basically, a properly torqued thread is sufficient.