drumburg

Member

- Location

- Wisconsin, USA

We build machines using supply voltages of 120Vac, 220Vac, and 480Vac. On our machines with 220+Vac we use an NFPA79 compliant Eaton disconnect. These machines are big enough to not have to worry too much about the added cost and space requirements.

However, our smaller 120Vac powered machines, usually tabletop, don't have room for a large disconnect to interlock the doors. I've reviewed the NFPA 79 2018 edition and just need a helping hand to see if we can use alternatives to an interlocking disconnect for these smaller machines.

According to 5.3.1.4 we would be required to interlock the control enclosure door but Exception No. 1 looks like we can use a key/tool removable dead-front cover to eliminate the interlock. My question here is: Are there specific requirements for a cover to be considered a dead-front cover other than preventing contact with exposed live parts? Such as material or construction. Does the enclosure also have to have a door or can we just use a bolt-on cover as the dead-front cover?

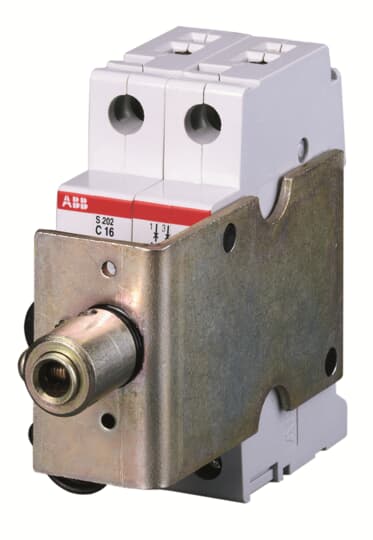

For another alternative, I have read in other forums that if all components in the control enclosure are IP20 (i.e. Touch Safe) then an interlock is not required although I haven't found that specifically in the NFP79 document.

However, our smaller 120Vac powered machines, usually tabletop, don't have room for a large disconnect to interlock the doors. I've reviewed the NFPA 79 2018 edition and just need a helping hand to see if we can use alternatives to an interlocking disconnect for these smaller machines.

According to 5.3.1.4 we would be required to interlock the control enclosure door but Exception No. 1 looks like we can use a key/tool removable dead-front cover to eliminate the interlock. My question here is: Are there specific requirements for a cover to be considered a dead-front cover other than preventing contact with exposed live parts? Such as material or construction. Does the enclosure also have to have a door or can we just use a bolt-on cover as the dead-front cover?

For another alternative, I have read in other forums that if all components in the control enclosure are IP20 (i.e. Touch Safe) then an interlock is not required although I haven't found that specifically in the NFP79 document.