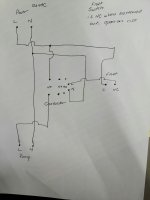

I have a float switch hooked up so it controls a 120 v single phase fuel tank pump. It is normally closed when the float bottoms out pumping fuel into the tank and opens when the float rises shutting the pump off I have the line coming in and branching off to a contactor and the other line going through the float switch and to the coil of that contactor. The neutral goes to the pump and also branches off to the coil of the contactor.

The switch is rated for 500 ma. The current should go through the switch to the relay coil which is 28 ma energizing it and then closing the contactor energizing the pump. I seem to have burned out the float switch. Any advice related to this project anyone has would be appreciated.

Thank you

The switch is rated for 500 ma. The current should go through the switch to the relay coil which is 28 ma energizing it and then closing the contactor energizing the pump. I seem to have burned out the float switch. Any advice related to this project anyone has would be appreciated.

Thank you