- Location

- Massachusetts

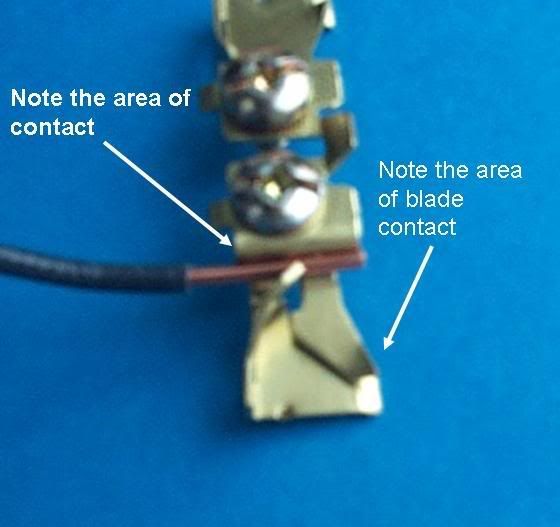

I look at it as a "surface area" contact issue. If you take a close look at backstabbing there is very little surface area contact between the wire and the device connection. In a properly terminated screw or clamp connection there is a much greater surface area of contact (provided they are tightened).

Without a doubt.

But what also needs to be looked at is costs. as George was hinting at is that if the customer has beat the contractors down to bargain basement pricing they are going to get the faster installation methods regardless if that means higher failure rates down the road.